Too much foam, too little beer - this is not only an issue when serving beer to customers. Foam can also become a problem in the brewery, specifically when it comes to the primary fermentation.

As we know, yeast works in different phases. The small bubble, thin layer of foam that forms after the yeast has been pitched is followed, after one or two days, by a cream-like foam of considerable thickness - known as the low Kräusen. None of this should pose a challenge to your brewing. However, If the yeast then really gets going and becomes more active in how it breaks down the extracted sugars, the so-called high Kräusen forms on the wort: brown-edged, large bubble, foam build-ups of considerable size. This excess of foam reduces the capacity of the fermentation tank. Believe it or not hops can help here, optimizing the tank efficiency by inhibiting foam.

Precious tank space

Cooling, insulation, temperature management, cleaning, disinfection, automation, monitoring and, last but not least, size and capacity are factors that make the tank space so valuable. The better it is utilized, the lower the production costs. When planning fermentation vessels, the additional space for the Kräusen has to be taken into account. For instance the space for foaming in lager beers in the fermentation tank can be a good 20 percent, for wheat beer, considerably more.

Move boundaries

More recently, breweries are facing increased pressure when it comes to producing beer as efficiently as possible. This means, they may have to re-evaluate their capacities. If new tanks are not immediately available because of economic or logistical constraints brewers have to work smarter when it comes to maximizing their capacity limits. If you are struggling with a drop in output or strongly varying production, it makes sense to use fewer tanks to their full capacity. Skillful tank utilization has a savings potential that should be exploited.

100% from hops

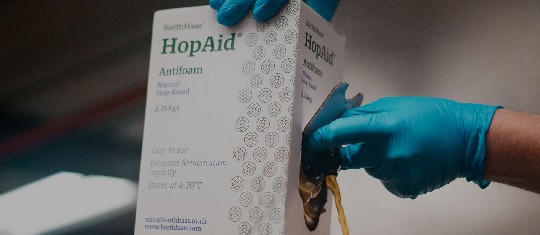

Hops have the solution for this. HopAid® Antifoam reduces the volume of foam during fermentation to ten per cent or even lower, and can completely prevent overfoaming. This means that not only can the tank capacity be utilized more efficienctly, butthe use of Hop Aid Antifoam saves labor, time and resources. There is no need for extensive cleaning, which can sometimes be caused by overfoaming. The risk of infection is also reduced.

Additional benefits

Other benefits of using HopAid® include simplifying cleaning of the tank thanks to less brandhefe (the remaining yeast stuck to tank walls after fermentation). It also increases the bitterness utilizationand protein yield in beer thanks to the lack of foam losses. So, optimizing tank occupancy allows you more than just additional beer to.

HopAid® Antifoam is a suspension of a specially prepared hop extract, a natural emulsifier and water. It can be easily added to fermentation tank before transferring of the cooled wort without any additional equipment. The BarthHaas Brewing Solutions team can consult on product dosage.

Less foam, more beer! We can ensure this during fermentation…simply.