For the hop harvest in 1956, the first hop-picking machine built in Germany under an English license was set up on the Barthhof farm in the Hallertau region - accelerating a structural change. Hand picking soon became a thing of the past.

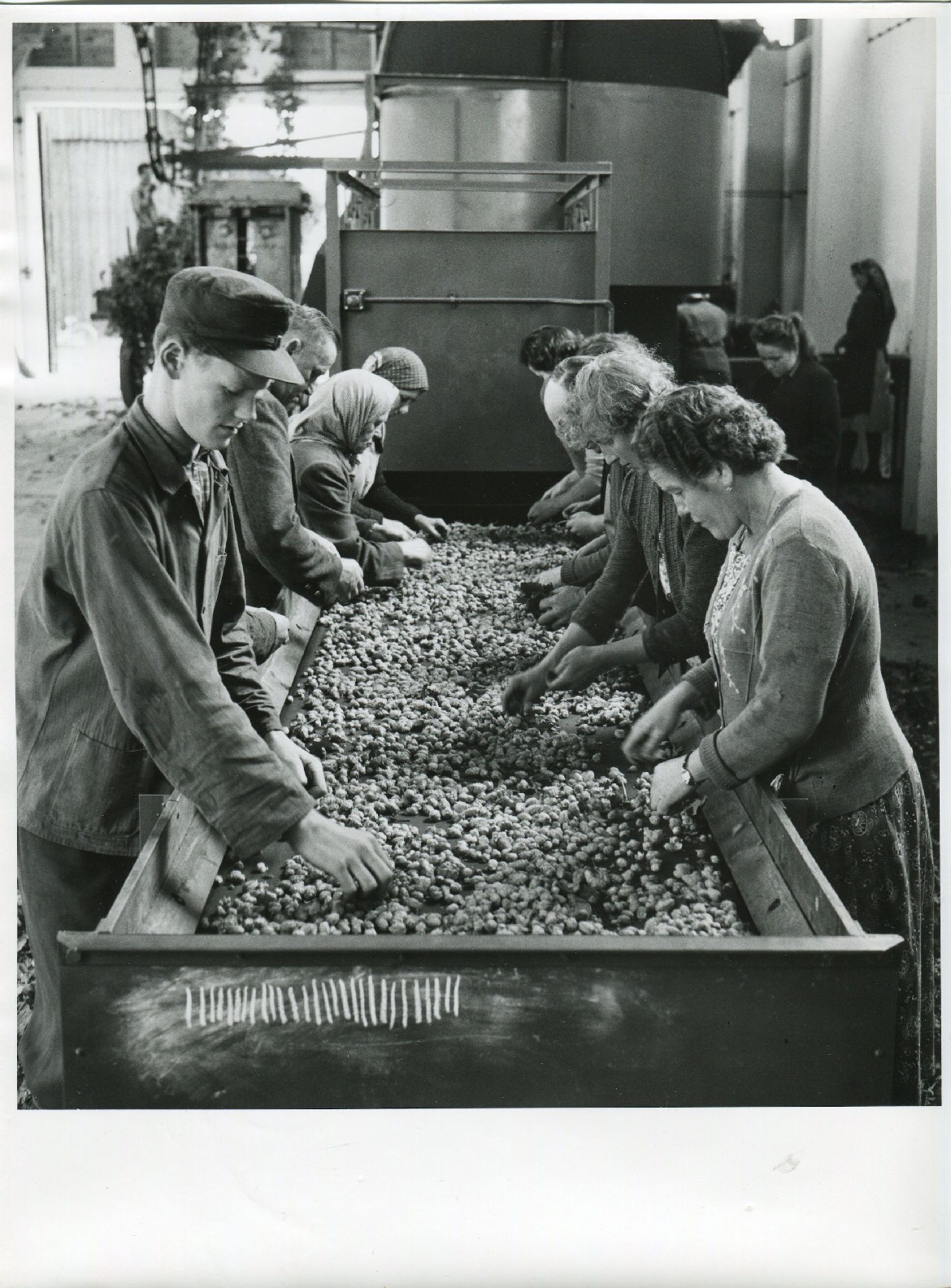

For decades, they dominated the scene at harvest time in the hop-growing regions of Hallertau, Spalt or Tettnang: whole trains of pickers who flocked to the fields to "pluck the hops". Often mothers with children were among them, because they were paid good money for three weeks and could also take their meals on the farms.

In the 1950s, however, the situation changed fundamentally; the economic miracle had a serious impact on hop growing as well: The industry urgently needed production workers; the former hop pickers found their steady livelihood, regular working hours and vacation times - so a trip to Italy during the summer vacations was now also more enticing than a harvesting assignment.

The old system reaches its limits

Soon, hop farmers were desperately looking for harvest workers. In the Hallertau region alone, an impressive 70,000 hop pickers were needed each year. When these were increasingly absent, wages were increased and people were picked up independently from their homes by buses. Some hop growers hired out pickers to each other. Under these conditions, it was no longer possible to harvest the crop in the long run. Not even on the Barthhof, a model hop-growing estate in Wolnzach, which was owned by the Barth family until the end of the 1970s. Another solution was needed.

In trade journals for hop cultivation, one read about hop picking machines in English-speaking countries, e.g., the Bruff machine from England, which alone was supposed to pick 700 bines per hour. The hop harvest would thus be done within a few hours, it was learned. Hop grower Leo Höfter was the first to take the risk and had the Bruff hop-picking machine imported from England to his estate in Neuhausen near Mainburg in 1955.

Barthhof finds solution at home

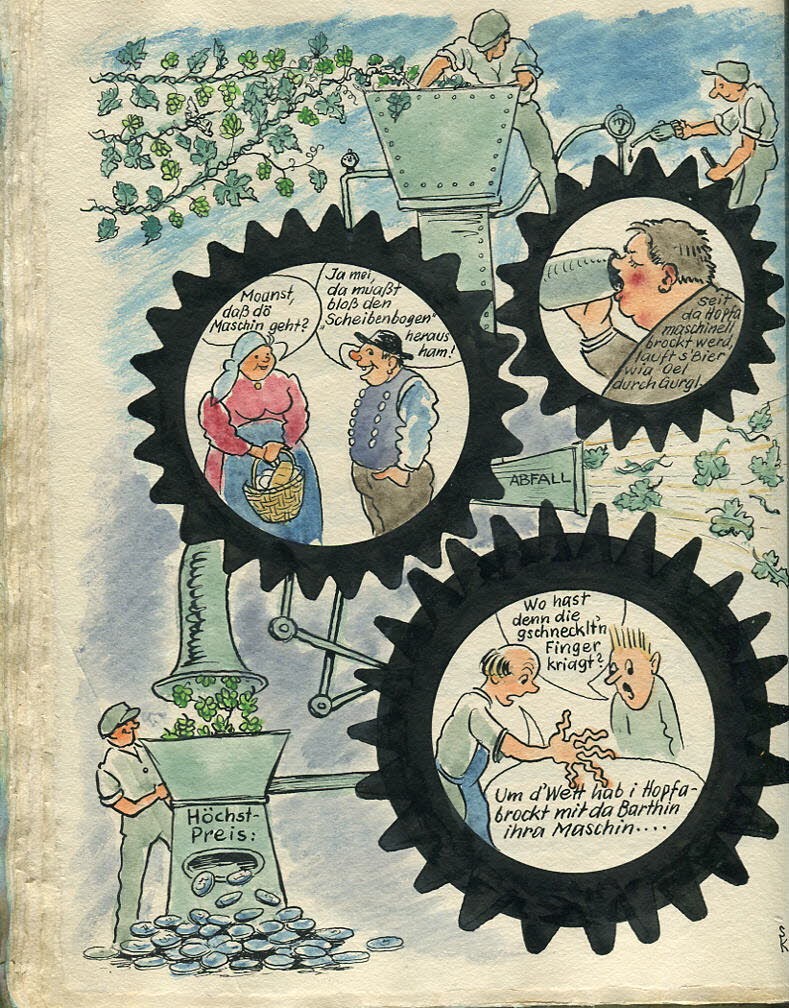

The owners of Barthhof inspected the Bruff machine at his place and were impressed, but balked at the high transport and customs costs for these huge machines. However, an alternative was soon found in their own homeland: Josef Scheibenbogen, owner of the machine-building factory of the same name in Landshut, had acquired a license from the English company Bruff to build hop-picking machines.

Scheibenbogen got into business with the Barthhof, and in 1956 the then owner Franziska Barth signed the purchase agreement with the company. The company undertook to deliver and assemble the first hop-picking machine built under English license in Germany by August 1, 1956. The Bruff Type B machine was smaller than the English model, but at 23 meters long and 8 meters high it was still enormous.

A new hall had to be built on the Barthhof site specifically for the installation. The purchase and construction of the new building required an investment of 80,000 to 90,000 deutschmarks. Farmers therefore took the state to task in granting reduced purchase loans and tax concessions.

Set-up attracts onlookers and media

The commissioning of the Bruff machine on the Barthhof for the 1956 hop harvest was a sensation. The people of Hallertau came to inspect the picking machine, and Bavarian radio reported on the event. Franziska Barth had a cartoon specially drawn in her guest book in which the hop bines put into the machine came out in coins at the highest price. At the Barthhof and in the Hallertau, people suspected that a memorable event had taken place. For in the years that followed, the hop-picking machine began its triumphant advance in hop cultivation, technically improved and more sophisticated.

The speed of change is astonishing - as early as 1964, 95 percent of the hop crop was harvested by machine. The hop-picking machine was the largest and most expensive agricultural machine of its time, and it changed hop cultivation profoundly. Witnesses from those days still wax lyrical today at the memory of the colossus' entry into everyday agricultural life.

Photo Credit: BarthHaas